Oscillating Drum Sander: A Comprehensive Guide

Are you looking to enhance your woodworking skills with a powerful and versatile tool? Look no further than the oscillating drum sander. This remarkable machine is designed to provide smooth, even finishes on wood surfaces, making it an essential piece of equipment for any woodworker. In this detailed guide, we’ll explore the features, benefits, and usage of an oscillating drum sander, ensuring you have all the information you need to make an informed decision.

Understanding the Oscillating Drum Sander

The oscillating drum sander is a precision tool that uses a rotating drum with abrasive paper to sand wood surfaces. Unlike traditional sanders, which move in a straight line, the drum sander oscillates back and forth, creating a more uniform finish. This movement helps to reduce sanding marks and provides a smoother surface.

Here’s a breakdown of the key components of an oscillating drum sander:

- Drum: The drum is the heart of the sander, rotating at high speeds to sand the wood. It’s typically made of metal and coated with abrasive paper.

- Oscillating Mechanism: This mechanism allows the drum to move in a side-to-side motion, ensuring a consistent and even finish.

- Table: The table is where you place the wood to be sanded. It should be flat and stable to ensure accurate sanding.

- Motor: The motor powers the drum and oscillating mechanism, providing the necessary force for sanding.

Benefits of Using an Oscillating Drum Sander

There are several advantages to using an oscillating drum sander over other sanding methods:

- Consistent Finish: The oscillating motion of the drum sander ensures a consistent finish, reducing the need for additional sanding.

- Reduced Sanding Marks: The side-to-side movement of the drum helps to eliminate sanding marks, resulting in a smoother surface.

- Increased Efficiency: The drum sander can cover more surface area in less time, making it a more efficient tool for large projects.

- Adjustable Sanding Pressure: Most drum sanders allow you to adjust the sanding pressure, ensuring the perfect finish for your project.

Choosing the Right Oscillating Drum Sander

When selecting an oscillating drum sander, consider the following factors:

- Size: Choose a sander that fits your workspace and the size of your projects. Larger sanders can handle wider boards, but they may be more difficult to maneuver.

- Power: Look for a sander with a powerful motor to ensure efficient sanding. A motor with at least 1 horsepower is recommended for most woodworking projects.

- Drum Size: The drum size will determine the width of the sanding surface. A drum size of 6 inches or more is ideal for most applications.

- Adjustable Sanding Pressure: An adjustable sanding pressure feature allows you to tailor the finish to your project’s needs.

- Price: Consider your budget and the features that are most important to you. While more expensive models may offer additional features, a mid-range sander can still provide excellent performance.

Using the Oscillating Drum Sander

Here’s a step-by-step guide on how to use an oscillating drum sander:

- Prepare the Wood: Ensure the wood is clean and dry before sanding. Remove any nails, screws, or other debris.

- Set Up the Sander: Place the sander on a stable surface and adjust the sanding pressure to your desired setting.

- Position the Wood: Place the wood on the table and ensure it’s centered. Adjust the table height to match the thickness of the wood.

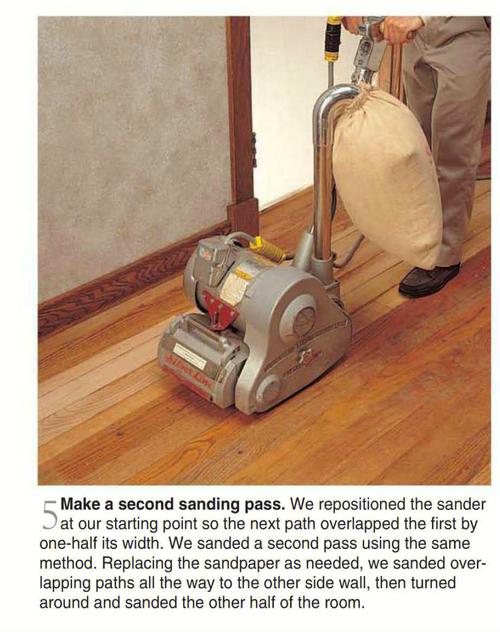

- Sand the Wood: Turn on the sander and slowly move it across the wood surface, maintaining a consistent pressure. Avoid pressing too hard, as this can cause sanding marks.

- Check the Finish: Periodically check the finish to ensure it’s even and smooth