Industrial Sand Sifter: A Comprehensive Guide

Are you in the market for an industrial sand sifter? If so, you’ve come to the right place. In this detailed guide, we’ll explore everything you need to know about industrial sand sifters, from their purpose and benefits to the different types available and how to choose the right one for your needs.

Understanding the Purpose of Industrial Sand Sifters

Industrial sand sifters are specialized machines designed to separate particles of sand from other materials. They are widely used in various industries, including construction, mining, and manufacturing. The primary purpose of these sifters is to ensure that the sand used in these industries meets specific quality standards.

By removing impurities and unwanted particles, sand sifters help improve the quality of the sand, making it more suitable for use in construction materials, glass production, and other applications. This not only enhances the performance of the final product but also extends the lifespan of machinery and equipment used in the process.

Benefits of Using Industrial Sand Sifters

There are several benefits to using industrial sand sifters:

-

Improved Quality: Sand sifters help ensure that the sand used in various applications meets the required quality standards.

-

Increased Efficiency: By removing impurities, sand sifters can improve the efficiency of the production process.

-

Cost Savings: High-quality sand can reduce the need for additional processing and improve the lifespan of machinery and equipment.

-

Environmental Benefits: By reducing waste and improving the quality of the sand, sand sifters contribute to a more sustainable approach to sand production.

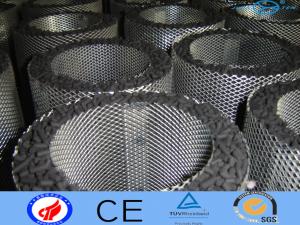

Types of Industrial Sand Sifters

There are several types of industrial sand sifters available, each with its unique features and applications. Here are some of the most common types:

| Type | Description | Applications |

|---|---|---|

| Shaker Screens | Consist of a series of screens that vibrates to separate particles. | Construction, mining, and glass production |

| Rotary Screens | Rotary drums with screens that rotate to separate particles. | Construction, mining, and foundry |

| De-watering Screens | Used to remove water from sand, making it more suitable for use in construction materials. | Construction and mining |

| High-frequency Screens | Use high-frequency vibrations to separate particles with a fine mesh. | Construction, mining, and glass production |

Choosing the Right Industrial Sand Sifter

When choosing an industrial sand sifter, it’s essential to consider several factors to ensure that you select the right machine for your needs:

-

Capacity: Determine the amount of sand you need to process per hour and choose a sifter with the appropriate capacity.

-

Particle Size: Consider the size of the particles you want to separate and choose a sifter with a screen mesh that matches your requirements.

-

Material: Ensure that the sifter is made from durable materials that can withstand the harsh conditions of your industry.

-

Power Source: Choose a sifter that can be powered by the available power source in your facility.

-

Brand Reputation: Research the reputation of the manufacturer and read reviews from other users to ensure you’re purchasing a reliable product.

Conclusion

Industrial sand sifters are essential machines for ensuring the quality of sand used in various industries. By understanding the purpose, benefits, types, and factors to consider when choosing a sifter, you can make an informed decision and select the right machine for your needs. Remember to research the manufacturer and read reviews to ensure you’re purchasing a reliable and durable product.