Sand Foundry MCQ: A Comprehensive Guide

Are you looking to dive deeper into the world of Sand Foundry? Do you want to test your knowledge with some MCQs (Multiple Choice Questions)? If yes, you’ve come to the right place. In this article, we will explore the various aspects of Sand Foundry and provide you with a detailed guide to help you understand and answer the MCQs effectively.

What is Sand Foundry?

Sand Foundry is a popular 3D printing technology that uses sand as the primary material. It is a form of binder jetting, where a liquid binder is selectively applied to the sand to create the desired shape. This technology is widely used in the aerospace, automotive, and other industries for its ability to produce complex geometries with high precision.

How Does Sand Foundry Work?

The Sand Foundry process involves several steps:

| Step | Description |

|---|---|

| 1 | Prepare the sand. The sand is typically mixed with a binder to make it moldable. |

| 2 | Use a laser or an electron beam to selectively cure the binder on the sand surface. |

| 3 | Repeat the curing process layer by layer to build the final part. |

| 4 | Remove the excess sand and binder to reveal the final part. |

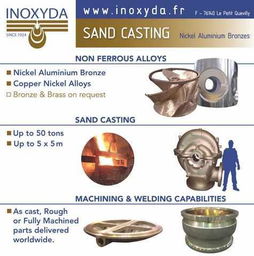

Types of Sand Foundry

Sand Foundry can be categorized into two main types based on the binder used:

- Organic Binder Sand Foundry: This type uses organic binders like phenolic, urethane, or polyurethane. These binders are suitable for producing parts with good mechanical properties.

- Inorganic Binder Sand Foundry: This type uses inorganic binders like sodium silicate or sodium silicate-based binders. These binders are suitable for producing parts with high thermal conductivity and good wear resistance.

Advantages of Sand Foundry

Sand Foundry offers several advantages over traditional manufacturing methods:

- Complex Geometries: Sand Foundry can produce complex geometries that are difficult or impossible to achieve with traditional methods.

- High Precision: The technology provides high precision, ensuring that the final part meets the required specifications.

- Cost-Effective: Sand Foundry can be a cost-effective solution for producing small to medium-sized batches of parts.

- Material Flexibility: The process can be used with various types of sand, allowing for a wide range of applications.

Applications of Sand Foundry

Sand Foundry is used in various industries, including:

- Aerospace: For producing complex components like turbine blades, engine parts, and airframe structures.

- Automotive: For producing engine components, exhaust systems, and other parts.

- Medical: For producing implants, surgical instruments, and other medical devices.

- Consumer Products: For producing consumer goods like jewelry, toys, and household items.

MCQs on Sand Foundry

Now that you have a basic understanding of Sand Foundry, let’s test your knowledge with some MCQs:

- What is the primary material used in Sand Foundry?

- A. Metal

- B. Plastic

- C. Sand

- D. Wood

- Which of the following is a type of binder used in Sand Foundry?

- A. Sodium silicate

- B. Phenolic

- C. Urethane

- D. All of the above

-

function pinIt() {

var e = document.createElement('script');

e.setAttribute('type','text/javascript');

e.setAttribute('charset','UTF-8');

e.setAttribute('src','https://assets.pinterest.com/js/pinmarklet.js?r='+Math.random()*99999999);

document.body.appendChild(e);

}