Green Sand Testing Procedure: A Comprehensive Guide

Green sand testing is a crucial process in foundry operations, ensuring the quality and reliability of castings. This guide will walk you through the entire procedure, from preparation to evaluation, providing you with a detailed understanding of each step involved.

Materials and Equipment

Before diving into the green sand testing procedure, it’s essential to gather all the necessary materials and equipment. Here’s a list of items you’ll need:

- Green sand mix

- Water

- Flask

- Scale

- Green sand mold

- Pattern

- Heat gun

- Thermometer

- Microscope

- Calipers

Preparation

Proper preparation is key to a successful green sand testing procedure. Here’s what you need to do:

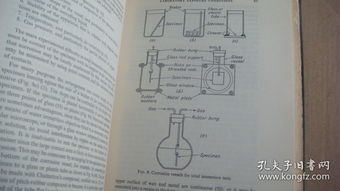

- Mix the green sand mix with water in a flask, following the manufacturer’s instructions.

- Ensure the mixture is well-mixed and free of lumps.

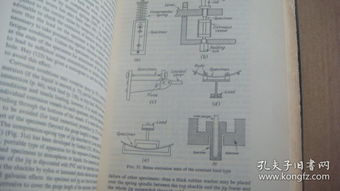

- Prepare the mold by placing the pattern inside and ensuring it’s properly aligned.

- Check the mold’s dimensions using calipers to ensure it meets the required specifications.

Green Sand Molding

Now that you have the mold prepared, it’s time to fill it with green sand. Follow these steps:

- Fill the mold with the green sand mixture, ensuring it’s evenly distributed.

- Use a trowel to compact the sand, removing any air pockets.

- Remove excess sand from the mold’s surface using a straight edge.

- Check the mold’s dimensions again to ensure it’s still within the required specifications.

Pattern Removal

Once the green sand has been molded, it’s time to remove the pattern. Here’s how to do it:

- Use a heat gun to soften the sand around the pattern.

- Gradually remove the pattern from the mold, being careful not to damage the casting.

- Inspect the casting for any defects or imperfections.

Heat Treatment

Heat treatment is an essential step in the green sand testing procedure. It helps to remove any residual moisture and improve the casting’s strength. Follow these steps:

- Place the casting in an oven and heat it to the recommended temperature.

- Keep the casting at the specified temperature for the required duration.

- Gradually cool the casting in the oven to prevent cracking.

Inspection and Evaluation

After the heat treatment, it’s time to inspect and evaluate the casting. Here’s what to look for:

- Check the casting for any cracks, porosity, or other defects.

- Measure the casting’s dimensions using calipers to ensure it meets the required specifications.

- Use a microscope to examine the casting’s surface and internal structure for any imperfections.

Results and Analysis

Based on the inspection and evaluation, you can now analyze the results. Here are some key points to consider:

- Compare the casting’s dimensions to the required specifications.

- Assess the casting’s surface quality and internal structure.

- Identify any defects or imperfections and determine their causes.

Conclusion

Green sand testing is a critical process in foundry operations, ensuring the quality and reliability of castings. By following this comprehensive guide, you can effectively prepare, mold, inspect, and evaluate green sand castings, ultimately improving the overall quality of your foundry products.