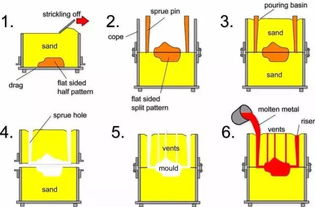

Sand Casting Products: A Detailed Overview

Have you ever wondered about the variety of products that can be created through sand casting? This ancient metalworking technique, which dates back to ancient civilizations, continues to be a popular choice for producing complex metal parts. In this article, we will delve into the world of sand casting products, exploring their applications, advantages, and some notable examples.

Applications of Sand Casting

Sand casting is a versatile process that can be used to produce a wide range of products. Here are some of the most common applications:

-

Automotive industry: Sand casting is widely used in the automotive industry for producing engine blocks, cylinder heads, and other engine components.

-

Aerospace industry: This technique is also employed in the aerospace industry for manufacturing aircraft components, such as landing gear, engine parts, and airframes.

-

Construction equipment: Sand casting is used to produce parts for construction equipment, such as excavator buckets, backhoe frames, and loader buckets.

-

Machine tools: Sand casting is a common method for producing machine tool components, such as spindles, gears, and bases.

-

Consumer goods: This technique is also used in the production of consumer goods, such as lawn mowers, washing machines, and refrigerators.

Advantages of Sand Casting

There are several advantages to using sand casting for manufacturing metal parts:

-

Cost-effective: Sand casting is a relatively inexpensive process compared to other metalworking techniques, making it an attractive option for both small and large-scale production.

-

Complex shapes: Sand casting allows for the production of complex shapes and intricate details, which can be challenging to achieve with other methods.

-

High accuracy: With proper technique and equipment, sand casting can produce parts with high accuracy and precision.

-

Material versatility: Sand casting can be used with a variety of metals, including aluminum, steel, brass, and bronze.

-

Customization: Sand casting allows for customization of parts, as the mold can be easily modified to accommodate specific design requirements.

Notable Examples of Sand Casting Products

Here are some notable examples of products that have been produced through sand casting:

| Product | Industry | Description |

|---|---|---|

| Engine block | Automotive | A large, complex part that houses the engine’s cylinders, pistons, and other components. |

| Cylinder head | Automotive | A component that covers the top of the engine block and contains the combustion chambers and valves. |

| Exhaust manifold | Automotive | A component that collects the exhaust gases from the engine and directs them to the exhaust system. |

| Jet engine turbine | Aerospace | A critical component of a jet engine that converts thermal energy into mechanical energy. |

| Engine case | Machine tools | A housing for the motor and other components of a machine tool. |

| Refrigerator compressor | Consumer goods | A component that compresses the refrigerant gas, causing it to release heat and cool the refrigerator’s interior. |

These examples highlight the versatility and widespread use of sand casting in various industries. The ability to produce complex shapes and intricate details makes sand casting an invaluable technique for manufacturers around the world.

Conclusion

Sand casting remains a popular choice for producing metal parts due to its cost-effectiveness, versatility, and ability to produce complex shapes. As technology continues to advance, sand casting is likely to remain a key method for manufacturing a wide range of products across various industries.