Understanding Crush Sand Density: A Comprehensive Guide

Crush sand density, often referred to as the specific gravity of crushed sand, is a crucial property that determines the quality and suitability of the material for various construction applications. In this detailed guide, we will explore the concept of crush sand density, its significance, measurement methods, and its impact on construction projects.

What is Crush Sand Density?

Crush sand density is a measure of the mass of crushed sand per unit volume. It is an essential property that helps engineers and contractors assess the quality of the sand and its suitability for different construction purposes. The density of crushed sand can vary depending on several factors, including the source of the sand, the crushing process, and the presence of impurities.

Significance of Crush Sand Density

The density of crushed sand plays a vital role in determining its strength, stability, and workability. Here are some key reasons why crush sand density is significant:

-

Strength: Higher density indicates greater strength, making the sand suitable for applications where structural integrity is crucial.

-

Stability: Dense crushed sand provides better stability in foundations and other structural elements, reducing the risk of settlement and failure.

-

Workability: The density of crushed sand affects its workability, which is essential for achieving the desired consistency and finish in concrete and mortar mixtures.

Measurement of Crush Sand Density

Several methods can be used to measure the density of crushed sand. The most common methods include:

-

Water Displacement Method: This method involves measuring the volume of crushed sand and then determining its mass by immersing it in water. The difference in mass before and after immersion gives the density.

-

Hydrometer Method: The hydrometer method is another common technique for measuring the density of crushed sand. It involves measuring the sand’s specific gravity using a hydrometer and then calculating the density based on the specific gravity value.

-

Direct Measurement Method: In this method, the density of crushed sand is measured directly using a density meter or a pycnometer. This method is often used in industrial settings where quick and accurate measurements are required.

Factors Affecting Crush Sand Density

Several factors can influence the density of crushed sand. Some of the key factors include:

-

Source of Sand: The type of rock from which the sand is derived can affect its density. For example, sand from granite has a higher density compared to sand from limestone.

-

Crushing Process: The method used to crush the sand can impact its density. Different crushing equipment and techniques can result in varying densities.

-

Size of Sand Particles: The size of the sand particles can influence its density. Generally, finer particles tend to have higher densities.

-

Moisture Content: The moisture content of the sand can significantly affect its density. Higher moisture content can lead to lower densities.

Impact of Crush Sand Density on Construction Projects

The density of crushed sand can have a significant impact on construction projects. Here are some examples:

-

Foundation Stability: A higher density of crushed sand ensures better stability in foundations, reducing the risk of settlement and failure.

-

Concrete Quality: The density of crushed sand affects the quality of concrete, influencing its strength, durability, and workability.

-

Earthwork Projects: In earthwork projects, the density of crushed sand can impact the stability and performance of embankments and retaining walls.

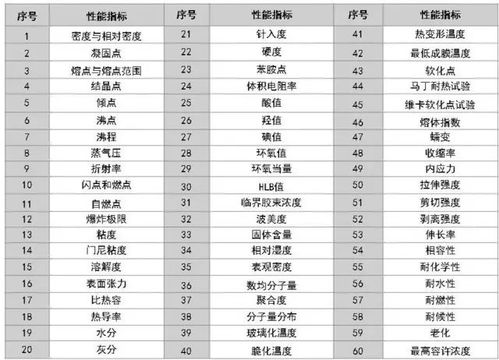

Table: Crush Sand Density Comparison

| Material | Crush Sand Density (kg/m鲁) |

|---|---|

| Granite Sand | 2.60 – 2.75 |

| Limestone Sand | 2.50 – 2.60 |

| Quartz Sand | 2.60 – 2.75 |