Sand Blasting Glass Machine: A Comprehensive Guide

Are you looking to add a unique touch to your glass projects? Do you want to understand the intricacies of a sand blasting glass machine? Look no further! This article will delve into the details of sand blasting glass machines, covering their types, uses, benefits, and maintenance. Whether you are a hobbyist or a professional, this guide will equip you with the knowledge to make informed decisions.

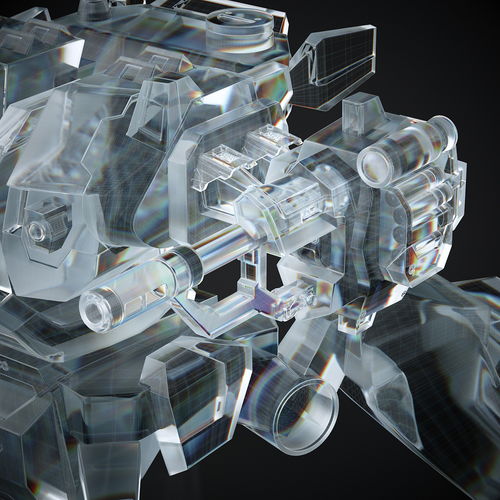

Understanding Sand Blasting Glass Machines

A sand blasting glass machine is a versatile tool used to create intricate designs, patterns, and textures on glass surfaces. It works by propelling a stream of abrasive material, usually sand, at high pressure onto the glass. This process removes material from the glass, leaving behind the desired design. Now, let’s explore the different types of sand blasting glass machines available in the market.

Types of Sand Blasting Glass Machines

1. Air Pressure Sand Blasting Machines

These machines use compressed air to propel the abrasive material at high speed. They are suitable for small to medium-sized projects and are relatively easy to operate.

2. Water Jet Sand Blasting Machines

Water jet sand blasting machines use a combination of water and abrasive material to achieve a smooth finish. They are ideal for delicate designs and can handle large glass surfaces.

3. Electric Motor Sand Blasting Machines

Electric motor sand blasting machines are more powerful and efficient than air pressure machines. They are suitable for heavy-duty projects and can handle large glass panels.

Applications of Sand Blasting Glass Machines

1. Artistic Glass Projects

Sand blasting glass machines are widely used in the creation of artistic glass pieces, such as stained glass windows, mirrors, and decorative glass panels.

2. Industrial Applications

These machines are also used in the industrial sector for etching glass, removing paint, and preparing surfaces for coating.

3. Automotive Industry

In the automotive industry, sand blasting glass machines are used to remove old paint, rust, and other contaminants from glass surfaces.

Benefits of Using Sand Blasting Glass Machines

1. Versatility

Sand blasting glass machines can be used on various types of glass, including flat, curved, and textured surfaces.

2. Precision

The high-pressure stream of abrasive material ensures precise and detailed designs.

3. Cost-Effective

Compared to other glass finishing methods, sand blasting is a cost-effective solution for creating unique glass designs.

Maintenance of Sand Blasting Glass Machines

1. Regular Cleaning

After each use, clean the machine to remove any abrasive material or debris. This will prevent clogs and ensure smooth operation.

2. Check for Leaks

Regularly inspect the machine for leaks in the air or water lines. Leaks can lead to inefficiency and potential damage.

3. Replace Worn Parts

Over time, parts such as nozzles and filters may become worn. Replace these parts to maintain optimal performance.

Conclusion

Investing in a sand blasting glass machine can open up a world of possibilities for your glass projects. With the right knowledge and care, these machines can provide you with years of reliable service. Whether you are a hobbyist or a professional, a sand blasting glass machine is a valuable tool to have in your arsenal.

| Machine Type | Application | Benefits |

|---|---|---|

| Air Pressure | Small to medium-sized projects | Easy to operate, cost-effective |

| Water Jet | Delicate designs, large glass surfaces | Smooth finish, versatile |

| Electric Motor | Heavy-duty projects, large glass panels | Powerful, efficient |