Understanding the Glass Sand Timer Manufacturer: A Comprehensive Guide

Are you in the market for a glass sand timer manufacturer? If so, you’ve come to the right place. In this detailed guide, we’ll explore the various aspects of glass sand timer manufacturing, from the materials used to the production process and the benefits of using these timers. Let’s dive in.

Materials Used in Glass Sand Timers

When it comes to glass sand timers, the quality of the materials used is crucial. Here’s a breakdown of the materials commonly used in their production:

| Material | Description |

|---|---|

| Glass | High-quality, durable glass is used to create the timer’s outer shell. It should be clear and resistant to scratches and shattering. |

| Sand | Specialty sand is used to fill the timer. It should be fine-grained and non-reactive to ensure accurate timing and a long lifespan. |

| Sealant | A high-quality sealant is used to prevent sand leakage and ensure the timer remains airtight. |

These materials are carefully selected to ensure the timer’s durability, accuracy, and overall performance.

Production Process

The production process of glass sand timers involves several steps, each crucial to the timer’s quality and functionality. Here’s an overview of the process:

-

Designing the Timer: The first step is to design the timer’s shape, size, and features. This is typically done using computer-aided design (CAD) software.

-

Creating the Mold: Once the design is finalized, a mold is created to shape the glass. This mold is often made of metal or plastic and is used to cast the timer’s outer shell.

-

Shaping the Glass: The glass is then melted and poured into the mold. It’s allowed to cool and harden before being removed from the mold.

-

Filling the Timer: The timer is filled with specialty sand, which is carefully measured to ensure accurate timing.

-

Sealing the Timer: A high-quality sealant is applied to the timer’s opening to prevent sand leakage and ensure airtightness.

-

Quality Control: The timer is then inspected for any defects or issues. If any are found, the timer is discarded or repaired.

-

Packaging: Once the timer passes quality control, it’s packaged and ready for shipment.

This meticulous process ensures that each glass sand timer meets the highest standards of quality and performance.

Benefits of Using Glass Sand Timers

Using glass sand timers offers several benefits, making them a popular choice for various applications. Here are some of the key advantages:

-

Accuracy: Glass sand timers are known for their accuracy. The fine-grained sand ensures consistent and reliable timing.

-

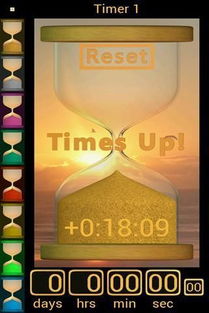

Visual Appeal: The clear glass and colorful sand create a visually appealing timer that can enhance any workspace or setting.

-

Durability: High-quality glass and materials ensure that glass sand timers are durable and long-lasting.

-

Customization: Many glass sand timer manufacturers offer customization options, allowing you to choose from various shapes, sizes, and colors.

-

Environmental Friendly: Glass sand timers are made from natural materials and are recyclable, making them an eco-friendly choice.

Whether you’re using a glass sand timer for cooking, meditation, or time management, these timers offer a reliable and visually appealing solution.

Choosing the Right Glass Sand Timer Manufacturer

With so many glass sand timer manufacturers out there, it’s essential to choose the right one for your needs. Here are some factors to consider when selecting a manufacturer:

-

Quality: Ensure that the manufacturer uses high-quality materials and follows a rigorous production process to ensure accurate and durable timers.

-

Customization Options: Look for a manufacturer that offers customization options