Contour Sanding Pads: A Comprehensive Guide

Contour sanding pads are a crucial tool in the world of woodworking and finishing. These pads are designed to provide a smooth and even finish to your projects, whether you’re working on furniture, cabinets, or any other wood-based item. In this detailed guide, we’ll explore the various aspects of contour sanding pads, including their types, uses, and benefits.

Types of Contour Sanding Pads

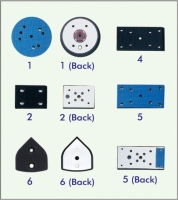

Contour sanding pads come in a variety of shapes and sizes, each designed to fit different contours and surfaces. Here are some of the most common types:

- Concave Pads: These pads are designed for sanding curved surfaces, such as the inside of bowls or the curves of furniture legs.

- Convex Pads: Convex pads are used for sanding convex surfaces, like the outside of bowls or the rounded edges of furniture.

- Flat Pads: Flat pads are perfect for sanding flat surfaces, such as the top of a table or the sides of a cabinet.

- Flexible Pads: Flexible pads can conform to a variety of shapes and contours, making them versatile for sanding irregular surfaces.

Materials Used in Contour Sanding Pads

The materials used in contour sanding pads can greatly affect their performance and durability. Here are some of the most common materials:

- Wood: Wooden pads are known for their durability and ability to provide a smooth finish. They are often used for sanding furniture and cabinets.

- Plastic: Plastic pads are lightweight and easy to handle. They are commonly used for sanding small, intricate surfaces.

- Aluminum: Aluminum pads are durable and can withstand high temperatures, making them ideal for sanding hot surfaces.

- Cellulose Fiber: Cellulose fiber pads are a popular choice for their affordability and effectiveness in sanding wood surfaces.

How to Choose the Right Contour Sanding Pad

Selecting the right contour sanding pad is essential for achieving a high-quality finish. Here are some factors to consider when choosing a pad:

- Shape and Size: Ensure that the pad fits the contour of the surface you’re sanding. Pads come in various shapes and sizes to accommodate different surfaces.

- Material: Choose a material that suits your project’s needs. For example, if you’re sanding a hot surface, an aluminum pad would be a better choice.

- Coating: Some pads come with a coating that helps to reduce friction and heat, which can be beneficial for sanding delicate surfaces.

Using Contour Sanding Pads

Using contour sanding pads is a straightforward process. Here’s a step-by-step guide on how to use them effectively:

- Attach the Pad: Secure the contour sanding pad to your orbital sander or random orbital sander.

- Select the Right Sandpaper: Choose a sandpaper grit that matches the level of finish you desire. Coarse grits are used for removing material, while fine grits are used for smoothing and finishing.

- Start Sanding: Begin sanding the surface in a consistent, overlapping pattern. Apply even pressure to avoid creating uneven spots.

- Check Your Work: Periodically check your work to ensure that the sanding is even and consistent. If necessary, adjust the sandpaper grit or pad.

- Clean the Surface: Once you’ve achieved the desired finish, clean the surface to remove any sanding dust or debris.

Benefits of Using Contour Sanding Pads

Contour sanding pads offer several benefits, making them an essential tool for woodworkers and finishers:

- Smooth Finish: Contour sanding pads help to create a smooth and even finish, which is crucial for a high-quality project.

- Time-Saving: These pads can save time by allowing you to sand complex contours and surfaces more efficiently.

- Cost