Diamond Core Sanding Pads: A Comprehensive Guide

Are you looking to enhance your sanding experience with diamond core sanding pads? These pads are a game-changer in the world of sanding, offering unparalleled performance and durability. In this detailed guide, we will delve into the various aspects of diamond core sanding pads, ensuring you have all the information you need to make an informed decision.

Understanding Diamond Core Sanding Pads

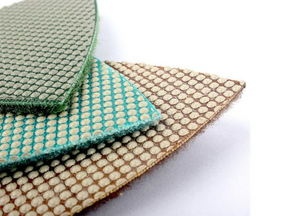

Diamond core sanding pads are designed with a unique core that provides exceptional performance. Unlike traditional sanding pads, which are typically made of foam or rubber, diamond core pads are constructed with a durable, non-slip core that ensures a stable and effective sanding process.

These pads are ideal for use with random orbital sanders, as they offer a consistent and smooth sanding action. The diamond particles embedded in the pad’s surface provide excellent cutting power, making them suitable for a wide range of applications, including woodworking, metalworking, and automotive projects.

Benefits of Diamond Core Sanding Pads

There are several key benefits to using diamond core sanding pads:

- Longevity: Diamond core pads are highly durable and can withstand heavy-duty use, making them a cost-effective choice in the long run.

- Efficiency: The diamond particles in the pads provide superior cutting power, allowing you to achieve a smooth finish in less time.

- Flexibility: These pads are available in various grit levels, allowing you to choose the perfect option for your specific project.

- Non-slip Surface: The non-slip core ensures that the pad stays securely in place during use, reducing the risk of accidents.

Choosing the Right Diamond Core Sanding Pad

When selecting a diamond core sanding pad, there are several factors to consider:

- Material: Ensure that the pad is made of high-quality materials, such as durable foam or rubber, to ensure longevity and performance.

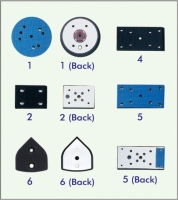

- Size: Choose a pad that fits your sander and the surface you are working on. Common sizes include 5″, 6″, and 8″.

- Grit Level: Select the appropriate grit level for your project. Fine grits (e.g., 180-220) are ideal for finishing, while coarse grits (e.g., 60-80) are better for initial sanding.

- Brand: Look for reputable brands that offer a wide range of diamond core sanding pads, ensuring you have the right option for your needs.

How to Use Diamond Core Sanding Pads

Using diamond core sanding pads is a straightforward process:

- Attach the Pad: Secure the diamond core sanding pad to your random orbital sander using the appropriate attachment.

- Select the Grit Level: Choose the appropriate grit level for your project, ensuring you achieve the desired finish.

- Start Sanding: Apply even pressure as you sand the surface, moving the pad in a circular motion. Avoid pressing too hard, as this can cause damage to the surface.

- Change Pads as Needed: Replace the pad when it becomes clogged with debris or when the grit level becomes too coarse for your project.

Common Uses of Diamond Core Sanding Pads

Diamond core sanding pads are versatile and can be used for a variety of applications:

- Woodworking: Achieve a smooth finish on wooden surfaces, including furniture, cabinets, and doors.

- Automotive: Sand and finish car bodies, wheels, and other metal surfaces.

- Metalworking: Sand and finish metal surfaces, including machinery, tools, and sculptures.

- Art and Craft: Create smooth finishes on various materials, such as glass, stone, and ceramics.

Conclusion

Diamond core sanding pads are an excellent choice for anyone looking to improve their sanding experience. With their superior performance, durability, and versatility, these pads are sure to become a valuable tool in your workshop. By following this comprehensive guide, you can make an informed decision