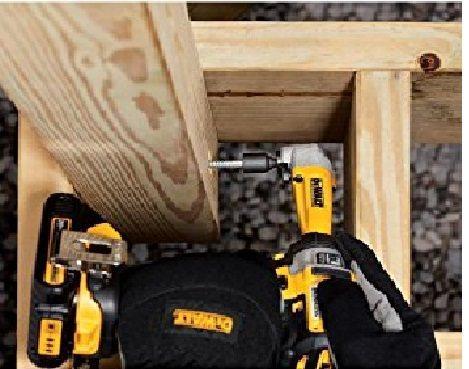

Drill Sand Attachment: A Comprehensive Guide

Drill sand attachments are essential tools in the oil and gas industry, providing support to boreholes during the drilling process. These attachments are designed to enhance the stability of the wellbore, reduce the risk of collapse, and improve the efficiency of drilling operations. In this article, we will delve into the various aspects of drill sand attachments, including their types, applications, benefits, and maintenance.

Types of Drill Sand Attachments

Drill sand attachments come in different types, each designed to cater to specific drilling conditions. The most common types include:

- Open Hole Sand Screens: These are used in open-hole drilling to prevent sand and other debris from entering the wellbore.

- Cased Hole Sand Screens: These are used in cased-hole drilling to protect the casing from sand and other debris.

- Submersible Sand Screens: These are used in deepwater drilling to prevent sand and other debris from entering the wellbore.

- Drill Collar Sand Screens: These are used to protect the drill collar from sand and other debris.

Applications of Drill Sand Attachments

Drill sand attachments are used in various drilling applications, including:

- Onshore Drilling: These attachments are used in onshore drilling operations to prevent sand and other debris from entering the wellbore.

- Offshore Drilling: Drill sand attachments are essential in offshore drilling operations, especially in deepwater environments, to prevent sand and other debris from entering the wellbore.

- Horizontal Drilling: These attachments are used in horizontal drilling operations to maintain the stability of the wellbore.

- Extended Reach Drilling: Drill sand attachments are used in extended reach drilling operations to prevent sand and other debris from entering the wellbore.

Benefits of Drill Sand Attachments

Drill sand attachments offer several benefits, including:

- Enhanced Wellbore Stability: These attachments help maintain the stability of the wellbore, reducing the risk of collapse and ensuring the safety of the drilling operation.

- Improved Drilling Efficiency: By preventing sand and other debris from entering the wellbore, drill sand attachments improve the efficiency of the drilling operation.

- Extended Well Life: These attachments help extend the life of the well by preventing sand and other debris from damaging the wellbore.

- Cost Savings: By improving the efficiency of the drilling operation and reducing the risk of wellbore collapse, drill sand attachments can lead to significant cost savings.

Maintenance of Drill Sand Attachments

Proper maintenance of drill sand attachments is crucial to ensure their optimal performance. Here are some key maintenance tips:

- Cleaning: Regularly clean the drill sand attachments to remove any debris or sediment that may have accumulated.

- Inspection: Regularly inspect the drill sand attachments for any signs of wear or damage. Replace any worn or damaged parts immediately.

- Storage: Store the drill sand attachments in a clean, dry, and well-ventilated area to prevent corrosion and damage.

- Training: Ensure that the personnel handling the drill sand attachments are properly trained on their use and maintenance.