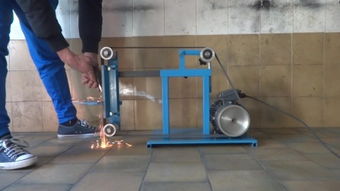

Sand Belt Grinder: A Comprehensive Guide

Are you looking to enhance your woodworking or metalworking projects? If so, a sand belt grinder might be the perfect tool for you. In this detailed guide, we will explore the various aspects of a sand belt grinder, including its features, benefits, and how to use it effectively.

Understanding the Basics

A sand belt grinder is a versatile tool that uses an abrasive belt to grind, sand, or polish materials. It is commonly used in woodworking, metalworking, and other industrial applications. Unlike traditional grinding wheels, sand belt grinders offer a more even and consistent finish, making them ideal for precision work.

Here’s a quick overview of the key components of a sand belt grinder:

- Motor: Powers the abrasive belt and determines the grinding speed.

- Abrasive Belt: The belt is made of abrasive material, such as silicon carbide or aluminum oxide, and comes in various grit sizes for different applications.

- Drive Pulley: Transmits power from the motor to the abrasive belt.

- Guides: Keep the abrasive belt in place and ensure even grinding.

Features to Consider

When choosing a sand belt grinder, there are several features to consider to ensure it meets your specific needs:

- Motor Power: Look for a motor with sufficient power to handle the materials you’ll be working with. Motors range from 1/2 horsepower to 3 horsepower.

- Belt Size: The size of the abrasive belt will determine the size of the workpiece you can grind. Common belt sizes include 4×24 inches, 6×24 inches, and 8×24 inches.

- Speed Control: Some sand belt grinders offer variable speed control, allowing you to adjust the grinding speed for different materials and applications.

- Adjustable Table: An adjustable table can help you achieve precise angles and contours for your workpieces.

- Safety Features: Look for grinders with safety features such as emergency stop buttons, overload protection, and dust collection systems.

Benefits of Using a Sand Belt Grinder

There are several benefits to using a sand belt grinder in your projects:

- Consistent Finish: Sand belt grinders provide a more even and consistent finish compared to traditional grinding wheels.

- Versatility: They can be used for a wide range of applications, including grinding, sanding, and polishing.

- Efficiency: Sand belt grinders are faster and more efficient than traditional methods, saving you time and effort.

- Cost-Effective: They are a cost-effective solution for achieving high-quality finishes without the need for expensive equipment.

How to Use a Sand Belt Grinder

Using a sand belt grinder is relatively straightforward, but it’s important to follow these steps to ensure safety and achieve the best results:

- Secure the Workpiece: Place your workpiece on the table and secure it using clamps or a vise.

- Select the Right Belt: Choose an abrasive belt with the appropriate grit size for your material and application.

- Adjust the Table: If necessary, adjust the table to achieve the desired angle or contour for your workpiece.

- Start the Grinder: Turn on the grinder and allow the abrasive belt to reach its operating speed.

- Grind the Workpiece: Hold the workpiece steady and move it across the abrasive belt in a controlled motion.

- Inspect and Repeat: Regularly inspect your workpiece for any imperfections and repeat the process as needed.

Common Uses of Sand Belt Grinders

Sand belt grinders are used in a variety of industries and applications, including:

- Woodworking: Shaping, sanding, and finishing wood pieces for furniture, cabinets, and other projects.

- Metalworking: Grinding, deburring, and finishing metal parts for automotive, aerospace, and other industries