Understanding the Sand Belt: A Comprehensive Guide

The sand belt, a versatile tool in various industries, is often overlooked for its simplicity. However, its role in sanding, grinding, and finishing processes is invaluable. In this detailed guide, we will explore the sand belt from multiple dimensions, providing you with a comprehensive understanding of its uses, types, and maintenance.

What is a Sand Belt?

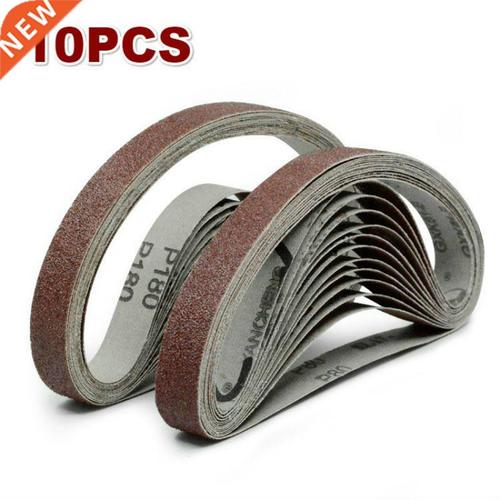

A sand belt is a continuous loop of abrasive material, typically made from sandpaper or an abrasive compound, coated onto a flexible belt. This belt is designed to remove material from a workpiece, providing a smooth and even finish. The sand belt is used in various applications, including woodworking, metalworking, and automotive industries.

Types of Sand Belts

There are several types of sand belts available, each designed for specific applications. Here are some common types:

| Type | Description |

|---|---|

| Aluminum Oxide | Excellent for general-purpose sanding and grinding tasks. |

| Zirconia | Highly durable and suitable for aggressive sanding and grinding. |

| Silicon Carbide | Great for cutting and shaping materials like wood and metal. |

| Diamond | Used for precision grinding and finishing on hard materials. |

Choosing the Right Sand Belt

Selecting the appropriate sand belt is crucial for achieving the desired results. Consider the following factors when choosing a sand belt:

-

Material: The type of material you are working on will determine the abrasive material you need. For example, aluminum oxide is suitable for general-purpose tasks, while diamond is ideal for hard materials.

-

Coating: The coating of the sand belt affects its durability and performance. Choose a coating that matches the abrasive material and the task at hand.

-

Coarse vs. Fine: The coarseness or fineness of the sand belt determines the amount of material removed from the workpiece. A coarse belt is suitable for aggressive sanding, while a fine belt is ideal for finishing.

Using a Sand Belt

Using a sand belt is straightforward, but there are a few tips to keep in mind:

-

Secure the workpiece: Ensure the workpiece is securely mounted to prevent movement during sanding.

-

Adjust the pressure: Apply even pressure to the workpiece while sanding. Too much pressure can damage the workpiece, while too little pressure may not provide the desired results.

-

Move in a straight line: Move the sand belt in a straight line across the workpiece to achieve an even finish.

Maintenance and Care

Proper maintenance and care are essential for extending the life of your sand belt. Here are some tips:

-

Regularly inspect the belt: Check for any signs of wear, such as frayed edges or worn-down abrasive material.

-

Store the belt properly: Keep the sand belt in a dry, cool place to prevent damage from moisture and heat.

-

Replace the belt when necessary: If the abrasive material is worn down or the belt is damaged, replace it to maintain optimal performance.

Conclusion

The sand belt is a versatile tool that can help you achieve a smooth and even finish on various materials. By understanding the different types of sand belts, choosing the right one for your task, and maintaining it properly, you can maximize the life and performance of your sand belt.