Sand Casting Kit UK: A Comprehensive Guide for Aspiring Makers

Are you an aspiring maker looking to delve into the world of metal casting? If so, a sand casting kit from the UK could be the perfect starting point. Sand casting, also known as mold casting, is a popular method for creating metal objects due to its versatility and relatively low cost. In this article, we will explore the various aspects of sand casting kits available in the UK, helping you make an informed decision for your casting needs.

Understanding Sand Casting

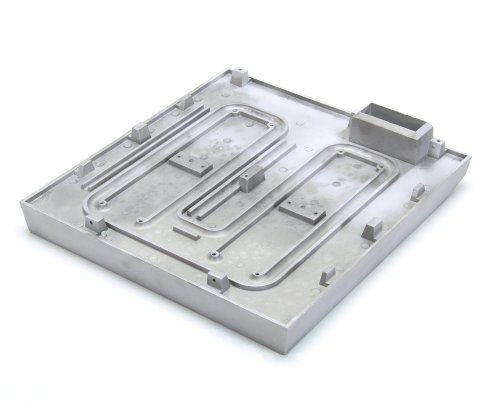

Sand casting involves creating a mold from sand, which is then used to pour molten metal into. The sand mold is made by packing sand around a pattern, which is the negative image of the desired object. Once the sand has hardened, the pattern is removed, leaving a cavity that is filled with molten metal. After cooling and solidification, the sand mold is broken away, revealing the cast metal object.

There are two main types of sand casting: green sand casting and dry sand casting. Green sand casting uses a mixture of sand, clay, and water, which provides better mold strength and allows for more complex shapes. Dry sand casting, on the other hand, uses dry sand and a binder, which is more suitable for simpler shapes and larger castings.

Choosing the Right Sand Casting Kit

When selecting a sand casting kit from the UK, it’s important to consider several factors to ensure you get the best value for your money. Here are some key aspects to keep in mind:

| Factor | Description |

|---|---|

| Kit Components | Ensure the kit includes all necessary components, such as sand, clay, patterns, and a furnace. |

| Material Quality | Choose a kit with high-quality materials to ensure better casting results. |

| Pattern Complexity | Select a kit with patterns that match your desired object’s complexity. |

| Price | Compare prices from different suppliers to find the best deal. |

Some popular sand casting kits available in the UK include:

- The Foundry Sand Casting Kit by Foundry Supplies

- The Basic Sand Casting Kit by Metaltech

- The Complete Sand Casting Kit by Castings Direct

Using Your Sand Casting Kit

Once you have your sand casting kit, it’s time to start casting. Here’s a step-by-step guide to help you get started:

- Prepare the sand by mixing it with clay and water to create a moldable mixture.

- Shape the sand around the pattern to create the mold cavity.

- Remove the pattern and ensure the mold is properly packed and compacted.

- Heat the metal in a furnace until it reaches the appropriate temperature for casting.

- Pour the molten metal into the mold cavity.

- Allow the metal to cool and solidify.

- Break away the sand mold and remove the cast metal object.

It’s important to note that sand casting can be a messy and time-consuming process, so be prepared to invest some effort and patience. Additionally, safety should always be a priority, especially when working with molten metal and hot equipment.

Advantages and Disadvantages of Sand Casting

Like any casting method, sand casting has its advantages and disadvantages. Here’s a breakdown of both:

Advantages

- Low cost: Sand casting is a cost-effective method for creating metal objects.

- High versatility: Sand casting can be used to create a wide range of shapes and sizes.

- Good surface finish: With proper technique, sand casting can produce high-quality finishes.

Disadvantages

- Complexity: Sand casting can be a complex process, requiring some skill and experience.

- Time-consuming: Sand casting can be time-consuming, especially for larger or more complex objects.

- Limitations on size: Sand casting is best suited for