Sand Casting Pattern Manufacturers: A Comprehensive Guide

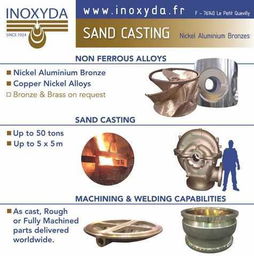

Are you looking for reliable sand casting pattern manufacturers? If so, you’ve come to the right place. Sand casting is a popular metal casting process that has been used for centuries. It involves creating a mold from sand, which is then used to pour molten metal into. This process is widely used in various industries, including automotive, aerospace, and construction. In this article, we will delve into the world of sand casting pattern manufacturers, providing you with a detailed and multi-dimensional introduction.

Understanding Sand Casting Patterns

A sand casting pattern is a replica of the final product that is used to create the mold. It is an essential component of the sand casting process, as it determines the shape and dimensions of the final casting. Patterns are typically made from wood, metal, or plastic, and they are designed to be durable and reusable.

When creating a sand casting pattern, several factors must be considered. These include the size and shape of the casting, the material being used, and the desired surface finish. The pattern must also be designed to allow for proper draft angles and allowances for shrinkage and cooling.

Types of Sand Casting Patterns

There are several types of sand casting patterns, each with its own advantages and applications. Here are some of the most common types:

| Type | Description | Applications |

|---|---|---|

| Single Pattern | Used for simple castings with a single piece. | Automotive parts, small machinery components |

| Match Plate Pattern | Used for castings with multiple pieces that fit together. | Engine blocks, pump housings |

| Cluster Pattern | Used for producing multiple castings simultaneously. | Automotive components, industrial machinery |

| Coreless Pattern | Used for castings with hollow interiors. | Valves, pipes |

The Role of Sand Casting Pattern Manufacturers

Sand casting pattern manufacturers play a crucial role in the sand casting process. They are responsible for designing, creating, and supplying patterns to foundries. Here are some key responsibilities of sand casting pattern manufacturers:

-

Designing patterns based on customer specifications and requirements.

-

Producing patterns using various materials and techniques.

-

Ensuring patterns are accurate, durable, and reusable.

-

Providing technical support and guidance to foundries.

Choosing the Right Sand Casting Pattern Manufacturer

Selecting the right sand casting pattern manufacturer is essential for the success of your sand casting project. Here are some factors to consider when choosing a manufacturer:

-

Experience and expertise: Look for manufacturers with a proven track record in the sand casting industry.

-

Quality control: Ensure the manufacturer has robust quality control processes in place.

-

Customization capabilities: Choose a manufacturer that can accommodate your specific design and material requirements.

-

Price and delivery: Compare prices and delivery times to find the best value for your project.

Benefits of Sand Casting Patterns

Using sand casting patterns offers several benefits, including:

-

Cost-effectiveness: Sand casting is a cost-effective method for producing complex metal parts.

-

Design flexibility: Patterns allow for the creation of intricate and detailed castings.

-

Material versatility: Sand casting can be used with a wide range of metals, including aluminum, steel, and brass.

-

Short lead times: Patterns can be produced quickly, allowing for faster production cycles.

Conclusion

When it comes to sand casting pattern manufacturers, it’s important to choose a reliable and experienced provider. By understanding the types of patterns available, the role of pattern manufacturers, and the benefits of sand casting,