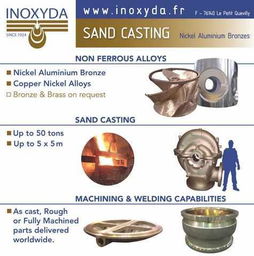

Sand Casting: A Comprehensive Guide

Sand casting, also known as sand mold casting, is a popular metal casting process that has been used for centuries. It involves creating a mold from sand, which is then used to produce metal parts. This method is favored for its versatility and cost-effectiveness, making it suitable for a wide range of applications. In this article, we will delve into the intricacies of sand casting, exploring its history, process, advantages, and applications.

History of Sand Casting

The origins of sand casting can be traced back to ancient civilizations, where it was used to produce tools and weapons. Over time, the process has evolved, with advancements in materials and techniques. Today, sand casting is still widely used in various industries, thanks to its unique benefits.

The Sand Casting Process

The sand casting process involves several steps, which are outlined below:

-

Pattern Creation: The first step is to create a pattern, which is a replica of the final metal part. This pattern is typically made from wood, metal, or plastic.

-

Mold Preparation: The pattern is then placed in a flask, which is a two-part mold. The flask is filled with sand, and the pattern is removed, leaving a cavity in the sand that matches the shape of the pattern.

-

Core Making: If the part requires internal cavities or cores, they are created separately and placed in the mold.

-

Mold Assembly: The flask is closed, and the mold is ready for casting.

-

Casting: Molten metal is poured into the mold, filling the cavity and cores.

-

Cooling and Shrinkage: The metal cools and shrinks, taking the shape of the mold.

-

Part Removal: Once the metal has cooled, the mold is broken open, and the casting is removed.

-

Finishing: The casting is then cleaned, trimmed, and finished to meet the required specifications.

Advantages of Sand Casting

Sand casting offers several advantages, making it a preferred choice for many applications:

-

Cost-Effectiveness: Sand casting is a relatively inexpensive process, making it suitable for high-volume production.

-

Complex Shapes: The sand mold can be easily modified, allowing for the production of complex shapes and intricate details.

-

Material Flexibility: Sand casting can be used with a wide range of metals, including aluminum, steel, and cast iron.

-

Short Lead Times: The process can be quickly set up and adjusted, resulting in shorter lead times for production.

Applications of Sand Casting

Sand casting is used in various industries, including:

-

Automotive: Engine blocks, cylinder heads, and transmission components are commonly produced using sand casting.

-

Aerospace: Sand casting is used to produce engine components, landing gear, and other critical parts.

-

Construction: Sand casting is used to produce pipes, valves, and other components used in construction projects.

-

Consumer Goods: Sand casting is used to produce a wide range of consumer products, such as lawn furniture, appliances, and sporting goods.

Challenges and Solutions in Sand Casting

While sand casting offers numerous benefits, it also presents some challenges:

-

Surface Finish: Sand casting can result in a rough surface finish, which may require additional finishing processes.

-

Dimensional Accuracy: The process can be prone to dimensional inaccuracies, which may require additional quality control measures.

-

Environmental Impact: Sand casting generates a significant amount of waste, which can be environmentally harmful.

These challenges can be addressed through the following solutions:

-

Improved Sand Molding Techniques: The use of advanced sand molding techniques, such as the use of resin-bonded sand, can improve surface finish and dimensional accuracy.

-

Quality Control: Implementing rigorous quality control measures can help ensure that the castings meet the required specifications.