Sheets of Glass Cut into Layered Wonders: A Detailed Exploration of Sand Blasted Edges

Imagine a world where sheets of glass are transformed into intricate masterpieces, each piece a testament to the artistry of glass cutting and the unique texture of sand blasted edges. This article delves into the fascinating process of creating layered glass sheets and the art of sand blasting, offering a comprehensive look at how these techniques come together to produce stunning visual effects.

Understanding Layered Glass Sheets

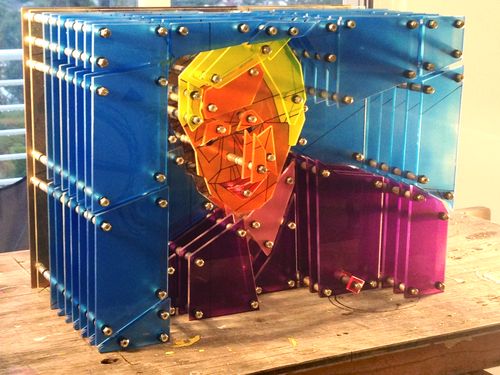

Layered glass sheets are a marvel of modern glass technology. They consist of multiple layers of glass, often with different colors or textures, fused together to create a single, durable panel. This process not only enhances the aesthetic appeal of glass but also adds functionality, such as increased strength and sound insulation.

Here’s a brief overview of the steps involved in creating layered glass sheets:

| Step | Description |

|---|---|

| 1. Glass Selection | Choosing the right type of glass, such as float glass or tempered glass, based on the desired properties and final application. |

| 2. Coloring | Applying color to the glass through various methods, such as dyeing, coating, or fusing with colored glass. |

| 3. Layering | Stacking the colored glass sheets on top of each other, with adhesives or other bonding agents used to hold them together. |

| 4. Fusing | Heating the layered glass sheets to a high temperature, causing them to melt and fuse together into a single, solid panel. |

| 5. Cooling and Cutting | Allowing the fused glass to cool slowly and then cutting it to the desired size and shape. |

The Art of Sand Blasting

Sand blasting is a technique used to create a textured surface on glass, metal, or other materials. When applied to glass, it adds a unique, tactile quality that can enhance the appearance of a piece and provide privacy or decorative elements.

Here’s how sand blasting works:

-

Prepare the glass surface by cleaning it thoroughly to remove any dirt or oils.

-

Position the glass in the sand blasting cabinet or booth.

-

Load the sandblasting media, which is typically a fine grain of sand or glass beads.

-

Adjust the pressure and flow rate of the sandblasting equipment to achieve the desired texture.

-

Operate the sandblasting gun, directing the sand media at the glass surface to create the desired pattern or texture.

-

After the sandblasting process is complete, clean the glass to remove any remaining sand media and inspect the surface for any imperfections.

Applications of Layered Glass with Sand Blasted Edges

Layered glass with sand blasted edges finds applications in various industries and settings, from residential to commercial. Here are some examples:

-

Residential: Sand blasted glass can be used in bathroom partitions, shower doors, and kitchen cabinets to add a touch of elegance and privacy.

-

Commercial: This type of glass is often used in office buildings, hotels, and retail spaces for partitions, windows, and decorative elements.

-

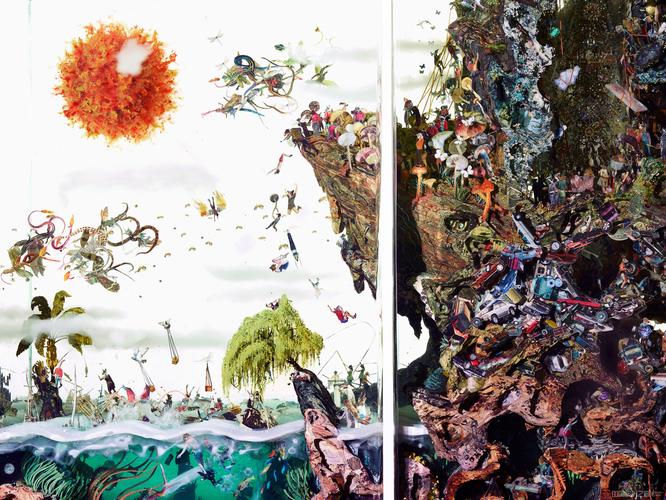

Art and Design: Artists and designers use layered glass with sand blasted edges to create unique pieces of art, such as sculptures, mirrors, and wall panels.

Conclusion

Sheets of glass cut into layered wonders with sand blasted edges represent the perfect blend of artistry and functionality. The process of creating these glass pieces is intricate and requires precision, but the end result is a stunning visual experience that can transform any space. Whether used for privacy, decoration, or functionality, layered glass with sand blasted edges is a versatile and captivating choice.