Sodium Aluminosilicate Dissolution-Precipitation Silica Sand: A Comprehensive Overview

Have you ever wondered about the process behind the creation of sodium aluminosilicate dissolution-precipitation silica sand? This unique material has gained significant attention in various industries due to its exceptional properties. In this article, we will delve into the details of this fascinating process, exploring its applications, benefits, and the science behind it.

What is Sodium Aluminosilicate Dissolution-Precipitation Silica Sand?

Sodium aluminosilicate dissolution-precipitation silica sand, often referred to as SAP sand, is a high-purity silica sand produced through a specific chemical process. It is primarily composed of silicon dioxide (SiO2), aluminum oxide (Al2O3), and sodium oxide (Na2O). The process involves dissolving the raw materials in a sodium hydroxide (NaOH) solution, followed by the precipitation of the silica particles.

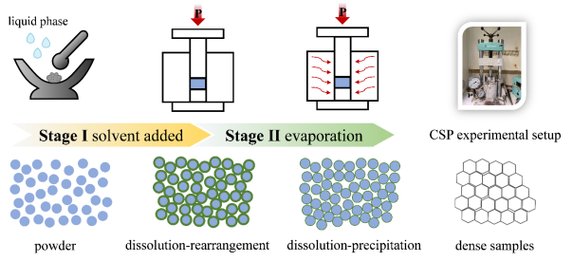

The Production Process

The production of SAP sand begins with the selection of high-quality raw materials. These materials are typically quartzite, feldspar, and clay. The quartzite serves as the primary source of silicon dioxide, while feldspar and clay contribute to the aluminum and sodium content, respectively.

Once the raw materials are collected, they are ground into a fine powder. The powder is then mixed with sodium hydroxide solution, creating a slurry. This slurry is heated and maintained at a specific temperature to facilitate the dissolution of the raw materials. The dissolved materials are then precipitated by adding a suitable acid, such as hydrochloric acid (HCl), to the solution. The resulting precipitate is filtered, washed, and dried to obtain the SAP sand.

Applications of SAP Sand

SAP sand finds applications in numerous industries due to its unique properties. Some of the primary applications include:

-

Foundry Industry: SAP sand is widely used in the foundry industry for the production of high-quality castings. Its high-purity and low-alkali content make it an ideal material for producing castings with excellent mechanical properties.

-

Glass Industry: SAP sand is a crucial raw material for the production of glass. Its high-purity and low-alkali content contribute to the production of high-quality glass products with excellent transparency and durability.

-

Building Materials: SAP sand is used in the production of bricks, tiles, and other building materials. Its high-purity and low-alkali content make it an ideal material for producing durable and environmentally friendly building products.

-

Chemical Industry: SAP sand is used as a catalyst in various chemical reactions. Its high-purity and low-alkali content make it an ideal material for ensuring the purity of the final product.

Benefits of SAP Sand

SAP sand offers several benefits over traditional silica sand, making it a preferred choice in various industries. Some of the key benefits include:

-

High Purity: SAP sand has a high-purity content, typically exceeding 99.9%. This ensures the production of high-quality products with excellent performance.

-

Low Alkali Content: SAP sand has a low-alkali content, which is crucial for industries such as glass and foundry. The low-alkali content prevents the formation of alkali inclusions, which can negatively impact the quality of the final product.

-

Excellent Mechanical Properties: SAP sand has excellent mechanical properties, such as high strength, good thermal stability, and resistance to wear and tear. This makes it an ideal material for various applications, including foundry, glass, and building materials.

Environmental Impact

The production of SAP sand is an environmentally friendly process. The raw materials used in the production are renewable and abundant. Additionally, the process minimizes waste generation, as the by-products can be recycled and reused. The low-alkali content of SAP sand also contributes to its environmental benefits, as it reduces the environmental impact of the final products.

Conclusion

Sodium aluminosilicate dissolution-precipitation silica sand is a high-purity, low-alkali material with numerous applications in various industries. Its production process is environmentally friendly, and its unique properties make it a preferred choice over traditional silica sand. As the demand for high-quality materials continues to grow, SAP sand is expected to play an increasingly important role in the future.